Curious what all that data in your logs actually means? Wondering how to apply it, what affects it, etc? Let’s take a dive into the world of engine log reading.

This is another Work In Progress (WIP) post, I’ll keep it updated as I learn more, receive feedback, etc…

I’ll start with what I know how to log and hopefully continue building this post up from there.

Pre-requisites for all logs

- The ability to log engine parameters

- Flash tunes such as MHD and BM3 allow full, high resolution (aka fast) data logging with lots of parameters

- Piggybacks such as the JB4 also allow high resolution logging but have a few less parameters

- OBD adaptors used in conjunction with apps like Torque on Android allow slow data logging with limited parameters.

- Make sure you are always logging the following parameters: Accel Pedal Position (MHD) or Pedal (JB4), Gear, RPM

- They should be by default, the gear and pedal parameters are very helpful determining where you’re at in your log

- A datazap.me account or something similar

- Click here for Datazap.me ‘s official video on how to import

- Ability to safely do multiple pulls (conditions change depending on what you’re logging)

Jump to

Intercooler aka FMIC log reading

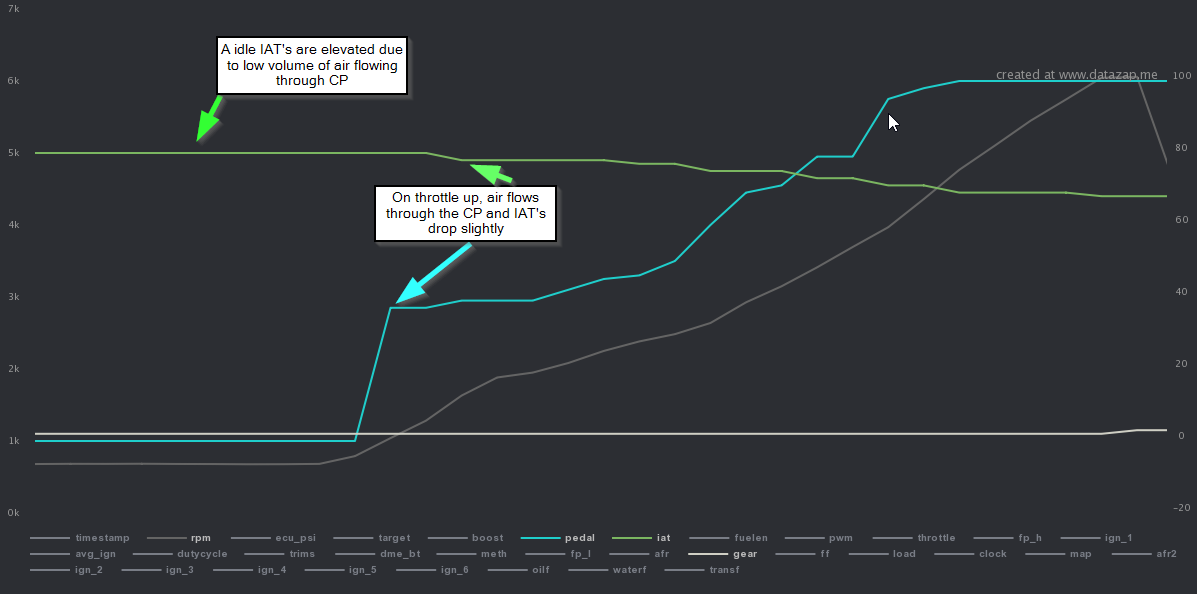

On the N55 platform the IAT (Intake Air Temperature) is measured on the chargepipe, after it’s gone through the intercooler. When I first purchased my CTSTurbo Intake I was concerned about high IAT’s because of the design of the intake, pulling in hot air from the engine bay. After many forum posts and much research I came to the conclusion that IAT is a function of the intercooler, not the fresh air intake.

Testing method

- The parameters you want ensure you are logging here are “IAT (Intake Air Temperature, Charge Air temperature), RPM, gear, pedal (aka accel pedal position)”

- Back to back WOT (wide open throttle) runs to redline (or close to it), through gears 2-4 or 3-5 or 2-5, whatever you can achieve safely

Reading Results

- The below .gif (NOT “JIFF”!!) is a JB4 log with an aftermarket CTS Turbo FMIC

- The initial dip in the IAT is because you start moving, it goes down because air is flowing through the intercooler/chargepipe at a much higher rate than idle

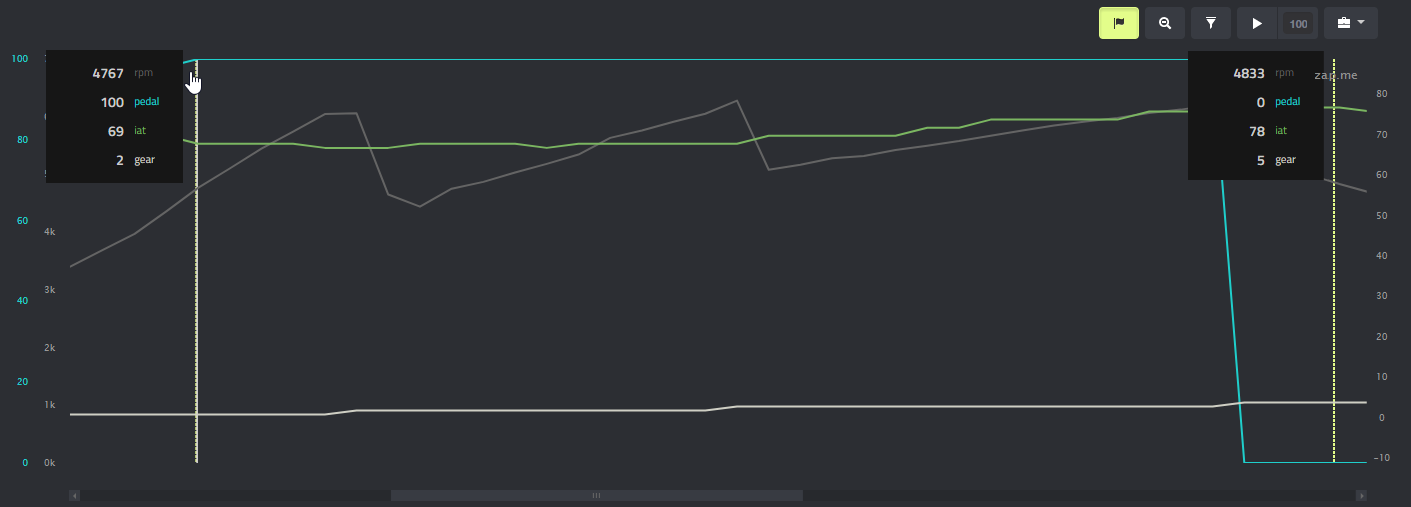

- Isolate out the initial drop in IAT (click and drag in Datazap.me) and take a look at your WOT time through the gears as seen below. You can add flags by double clicking the datazap chart

- So above we have a Wide Open Throttle pull through gears 2-4, we can see the green line drop initially as a lot more air starts flowing the system and then start to rise as the turbo charger heats up

- IAT’s climb overtime because the exhaust side of the turbo gets really hot and transfers some of that heat to the charge air side of the turbo

- The forums say a well performing intercooler should keep the IAT increase around 8-10 degrees on a short pull like this, on longer pulls you will see a larger increase in IAT’s but they should still be within 10-20º of the starting temperature

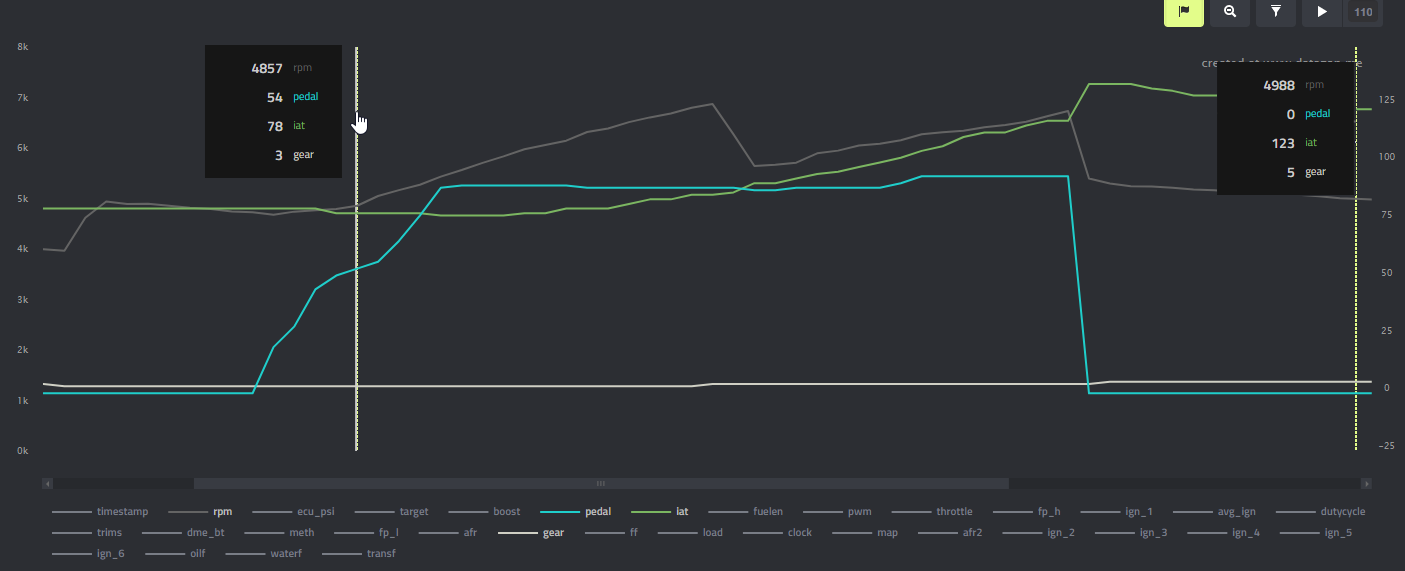

- In contrast, the below .gif is from fsociety, his log with stock intercooler.

- In this example you see IAT’s rise very quickly as the turbo heats up and the stock FMIC just can’t keep up. It started at 78º and ended at over 123º, a change of over 45ºF!

- The above demonstrates our stock FMIC getting “heat soaked” and losing it’s ability to effectively cool the charge air which can result in timing pulls amoung other things.

Engine Timing (MHD)

Now ignition timing is a very in depth area. There are SOO many variables when it comes to timing I can’t even begin to talk intelligently on them. What I can do though, is show you how to determine if your logs are showing you pulling timing.

Test Method

- In addition to the parameters in pre-req you want ensure you are logging “cyl 1-6 timing cor”

- Make sure traction control (DSC) is OFF

- Hold down the DSC button for about 5 seconds, I can’t tell you how many times I’ve forgotten to do this and the traction nanny steps in making the log invalid

- WOT run to redline (or close to it), starting optimally in gear 4 shifting to 5th gear still WOT for a second or two

- A 3rd gear WOT run will work as well, but it is a very short gear (8AT) so keep in that in mind

Reading the results

- The below .gif is a 4th gear pull

- If your “pulling timing” you will see negative values in your “cylX timing cor *” field as shown above.

- The mostly likely cause is fuel quality, aka octane rating, but that’s super simplifying it

- If it’s a large correction like a sudden drop over 3º is an indication of knock and the DME protecting the engine

- Other factors for pulls in timing are IAT, weak coil(s), weak plug(s) and more but I’m going to stop there, as I said above, I don’t know enough to intelligently speak on the subject at greater length.

Fuel Pressure (Identify a crash or weak fuel pump, MHD logs)

Are you using E85 in your tank? Have you had any instances of the engine stumbling at high RPM under high load? When I used too much E85 I had this happen, it was very disconcerting and kind of dangerous. I was on a highway on-ramp trying to accel quickly to freeway speeds and the car literally had no power for about 2-3 seconds and just stumbled over itself trying to accelerate. What I’ll try to demonstrate here is how to look for signs your fuel pump can’t keep up your fueling demands. The most likely cause of this in a car with stock a fueling system is the use of too much E85. While you’re probably not going to be logging when this does happen, in the case you were here is what to look for.

Test Method

- In addition to the parameters in pre-req you want ensure you are logging “Rail Pressure Mean PSI”

- Stumbling very apparent at high load and high RPM, engine fails to make power and kind of falls over itself

Reading the Results

- (Copied from my E85 post here) Something to be mindful of when adding more e85 is your “Rail Pressure Mean PSI”

- In your logs your “Rail Pressure Mean PSI” value should never dip below 1600psi or even come close for that matter, if it does, that may be an indication you’re using to much e85 and your fuel pump just can’t keep up, or your fuel pump maybe going bad (F30 N55 folks, make sure you’ve had your pump replaced via the recall)

- To dumb it down to my level, because I’m not the sharpest knife in the drawer… It takes much more e85 to deliver same energy as gasoline, the injectors have to inject more fuel and your fuel pump can’t keep up with that extra volume being sprayed through all the injectors, as a result your fuel rail pressure crashes. The overall PSI drops because the fuel pump is pumping as hard as it can.

- Thanks Joseph from the MHD beta for this info!

-

Pretty cool visual demonstrating more fuel, less PSI, RPM rises, injectors inject more, fuel rail pressure goes down

- In your logs your “Rail Pressure Mean PSI” value should never dip below 1600psi or even come close for that matter, if it does, that may be an indication you’re using to much e85 and your fuel pump just can’t keep up, or your fuel pump maybe going bad (F30 N55 folks, make sure you’ve had your pump replaced via the recall)

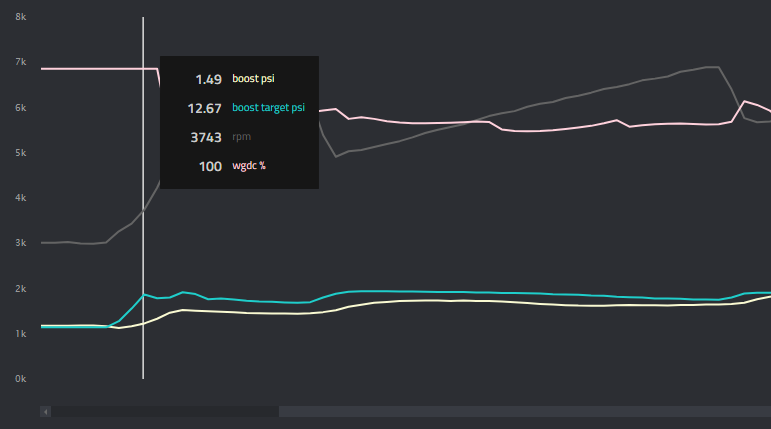

Boost Leak, boost below target

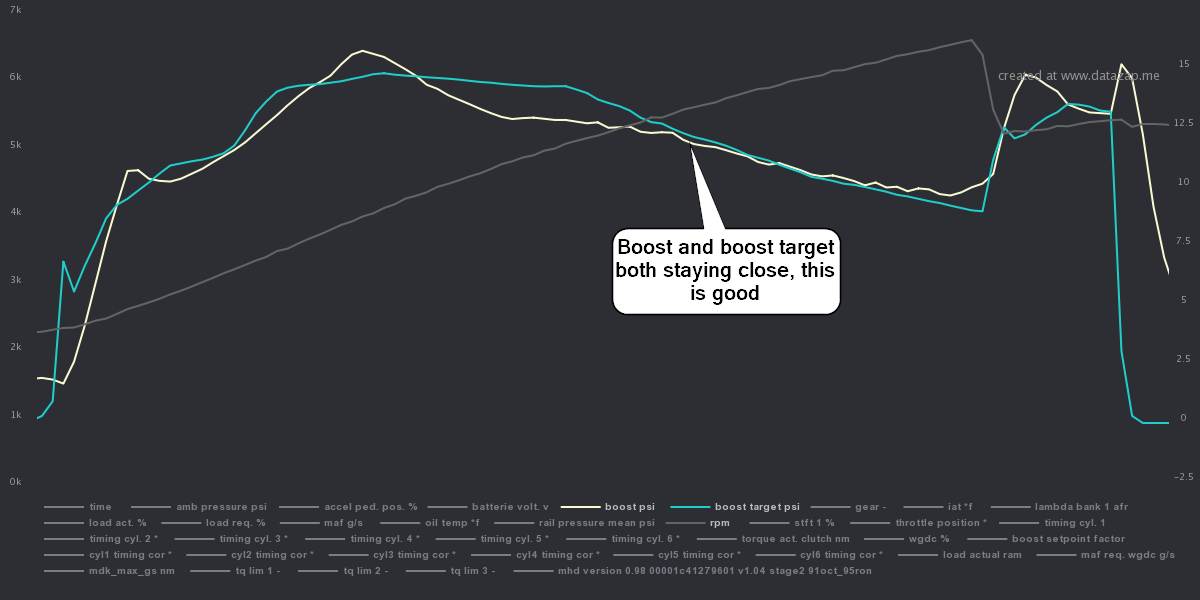

I recently asked on the forums what exactly constitutes a boost leak. I often see values 1 – 1.5 PSI below my target but not always, sometimes it’s above by about 1 – 1.5 PSI. The consensus on the forums is a boost level that consistently below by 2 PSI or greater is means for checking for a leak.

Test Method

- The parameters you want ensure you are logging here are “Boost PSI (Pre-Boost on JB4) and Boost Target (Target on JB4)”

- A nice 3rd or 4th gear medium to high load pull from low RPM to high RPM, you need a pull where you can see boost build from a low RPM and continue to pressurize through the higher RPM’s

Reading the Results

- Optimally your Boost PSI and Boost Target will be pretty close if not on top of each other as seen below:

- In the below JB4 example, you can see boost target pinned at 14 PSI but the actual boost missing by about 3-4 PSI, this is indicative of a boost leak

- And another example of a boost leak, this person just had their CP swapped out

Subscribe to the blog, I’ll be updating this post as I learn more! Contribute to the discussion! Am I wrong about something? Is something unclear? Let me know! Comment, contact me, find me on the forums, instagram, whatever! I just picked up this book on Amazon How to Tune and Modify Automotive Engine Management Systems. It came highly recommended on the forums, hoping I’ll learn a fair bit from it and share my experience here.

Great information for a beginner like myself, this post has helped me not feel overwhelmed.

Quick question, is it possible to use the MHD Data Logging license without having purchased their full OBD Flash unlocker and OTS Map? I understand it is sold separately, but will the logger still be able to grab all those parameters?

Glad to hear it, I find myself overwhelmed as well and use the blog as a brain dump (and reminder to myself of what I think I’ve learned.)

I’m pretty sure you can. Your best bet would be to send a quick email to mhd.tuning@gmail.com (or facebook message) to MHD just to be sure.

There logging is pretty awesome and much higher resolution (faster data rate) than any of the OBD2 loggers out there. When I started out I used an OBD2 to app on my phone and it was way to slow for any relevant data. It get’s you in the ballpark but it’s also pretty limited in terms of what parameters you can log.